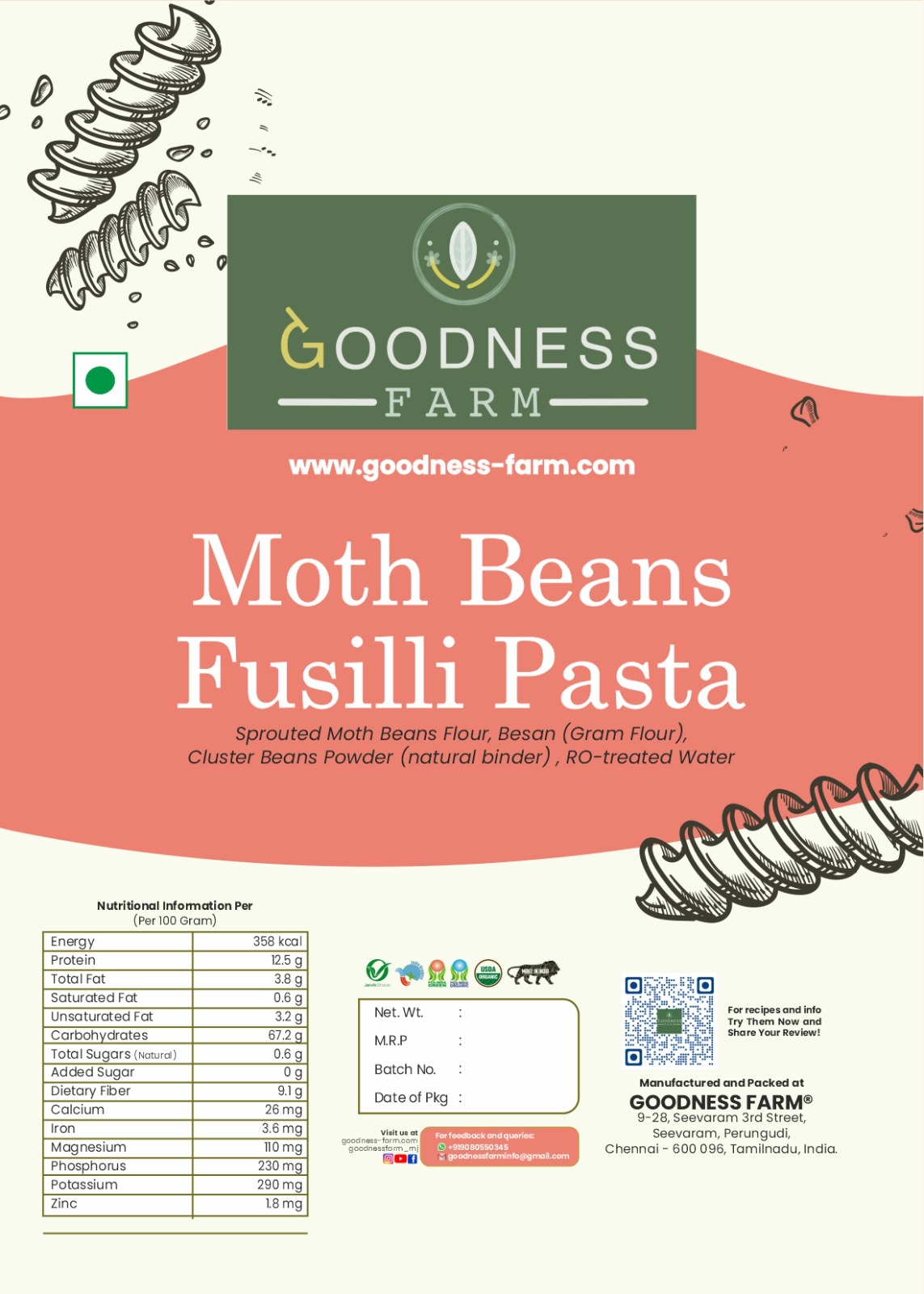

Moth Beans Fusili Pasta (180 G)

₹140.00

32 in stock

Processing of Moth Beans Fusili Pasta Using Sprouted Moth Beans Flour

Ingredients Composition

- Sprouted Moth Beans (Vigna aconitifolia) Flour – 70%

- Gram Flour (Chickpea Flour) – 15% (for additional protein and texture)

- Cluster Beans (Cyamopsis tetragonoloba) Powder – 10% (for fiber and health benefits)

- RO Treated Water – As required (for dough preparation)

- Cold-Pressed Coconut Oil – As required (optional, for dough smoothness)

🛠️ Processing Steps

1. Selection & Cleaning of Moth Beans

Top-quality moth beans are selected and cleaned through air classifiers and sieves to remove dirt and foreign matter.

The beans are washed thoroughly with RO-treated water to ensure purity.

2. Sprouting of Moth Beans

- Soaking: The moth beans are soaked in RO-treated water for 8–10 hours.

- Germination: After soaking, the beans are incubated at 28–30°C and ~80% humidity for 24–30 hours to sprout, enhancing nutrient availability and reducing anti-nutrients.

- Drying: The sprouted beans are dehydrated at temperatures <50°C to maintain the nutritional profile.

3. Milling into Flour

The dried sprouted moth beans are stone-ground into fine flour (~120 microns), preserving the protein, fiber, and essential vitamins.

4. Preparing Cluster Beans Powder

Cluster beans are selected, washed, and shade-dried to preserve their nutritional content. The dried cluster beans are then ground into a fine powder to be mixed into the pasta dough for added fiber and digestive benefits.

5. Blending the Flours

Sprouted moth beans flour, gram flour, and cluster beans powder are blended together in the correct proportions to achieve a smooth and workable dough.

Rock salt is added for flavor enhancement.

6. Dough Preparation

The dry flour mixture is gradually mixed with RO-treated water to form a smooth, elastic dough.

Cold-pressed coconut oil is added if required to improve the dough’s consistency and smoothness.

The dough is kneaded thoroughly and rested for 20–30 minutes for full hydration.

7. Fusili Pasta Extrusion

The dough is fed into a pasta extruder with a fusili die to form spiral-shaped pasta.

The pasta is shaped carefully to ensure uniformity and the perfect curl of the fusili.

8. Drying & Dehydration

The extruded fusili is laid out on trays and dried at 45–50°C to reduce moisture content below 10%, which helps extend the shelf life and improves firmness during cooking.

9. Packing & Storage

The dried fusili pasta is packed in eco-friendly, moisture-resistant packaging.

Shelf Life: 6–9 months when stored in a cool, dry place away from sunlight.

🌟 Nutritional & Functional Highlights

✅ Sprouted Moth Beans – Rich in protein, iron, and folate, improving muscle and tissue health.

✅ Gram Flour – Adds additional protein, fiber, and a slight nutty flavor, supporting digestion.

✅ Cluster Beans Powder – High in fiber, aids in digestion, and supports healthy gut microbiota.

✅ Low Glycemic Index – Helps maintain blood sugar levels, making it suitable for diabetic and weight-conscious individuals.

✅ Gluten-Free – Perfect for those with gluten sensitivity or celiac disease.

| Weight | 0.180 kg |

|---|

Reviews

There are no reviews yet.